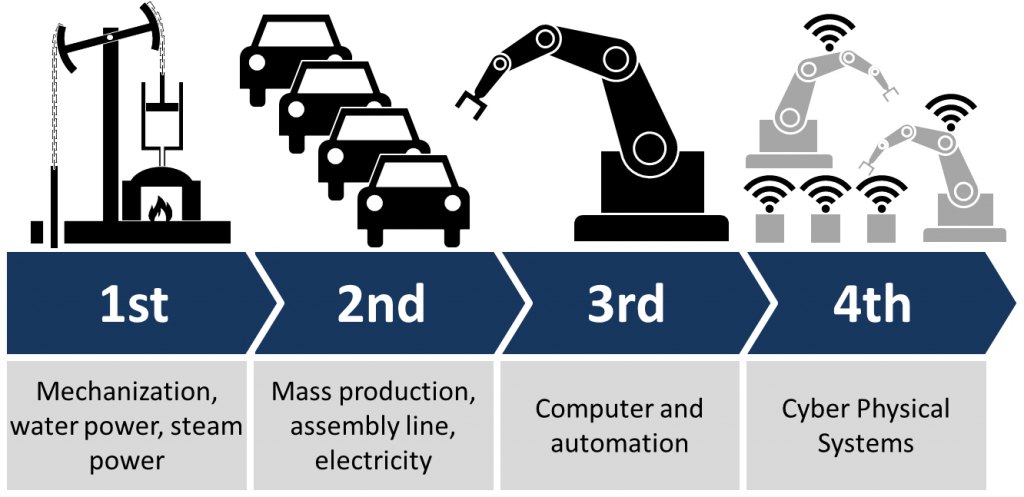

With IoT’s entrance into the industrial sector, our understanding of manufacturing is bound to change- and quick. Industrial IoT, or IIoT, is pushing forward the German coined “Industry 4.0”- essentially a smart facelift to manufacturing. With key characteristics like communicating devices, physical data used to contextualize actions and new machines able to assist humans in decision making as well as act autonomously, Industry 4.0 aspires to create a symbiotic relationship between cyber-physical systems and human beings. A great example of this is Lamborghini, a luxury brand that got a smart makeover after it’s been bought by Audi. The company has launched a new factory a few months ago, thus automating the manufacturing process- now guided by a special software and sensors.

The goal of Industry 4.0 is optimization, not invention- thus it’s often referred to as an evolution in the industry rather than a re-volution. The difference won’t be visible- no brand new gleaming skyscrapers for factories and futuristic machinery- but rather a pipeline that simply works. Interconnectivity, data collection and autonomous machines would make even errors easy to detect and easy to fix. It’s hardly surprising then that Lamborghini isn’t the only one willing to embrace the change: Cincinnati, for example, branded itself an “Industry 4.0 Demonstration city” and South Korea proclaimed intentions to have 30,000 smart factories by 2025. With a predicted 3.5 million new jobs in manufacturing as a result of IIoT and investments reaching nearly $189 billion just this past year- it’s safe to say that wide acceptance of IIoT is just a matter of time.

Industry 4.0’s possible implications go beyond the fate of specific companies or sectors, and may determine the path in which the global trade balance will go in the coming decades, and will even have effects on the global power balance. The U.S and China are competing for world economic hegemony, and are leveraging every aspect of their economies in that race. While the U.S is still first in terms of GDP, it is second to China in terms of manufacturing, with a 2017 industrial output reaching a record level of $2.2 trillion. Through the years the American industry has been taken over by China and low labor cost countries such as Mexico, Brazil and Asia-Pacific. The U.S intends to apply Industry 4.0 technologies in order to replace China as the world’s largest manufacturer. The “Industry 4.0 Market & Technologies. Focus on the U.S. – 2018-2023” report forecasts that the U.S. Industry 4.0 2016-2023 market will grow at a CAGR of 12.9%. This trend goes hand in hand with the Trump administration’s policy which is focused on empowering the American industrial sector and creating new jobs. During the administration’s first year, American factories have added jobs at the fastest pace since 2014.

Connecting factories- and connectivity in general- is a source of concern for smart factories and IIoT implementation. Many fear that smart factories might be a security hazard- running the risk of patents being stolen or whole plants getting shut down. Yet the cybersecurity threat is imminent everywhere nowadays, and stalling progress and possible improvement out of fear won’t stop the world in its tracks. Concerns around initial capital, skills gap and integration with legacy tech all shrink in the face of knowledge retention, real-time recovery, calculated efficiency and insight based on a collective experience across multiple locations.

Sources:

China and the US invest heavily in industry 4.0

Forbes: what everyone must know about industry 4.0